Plastisol Apparel Printing Company Near You

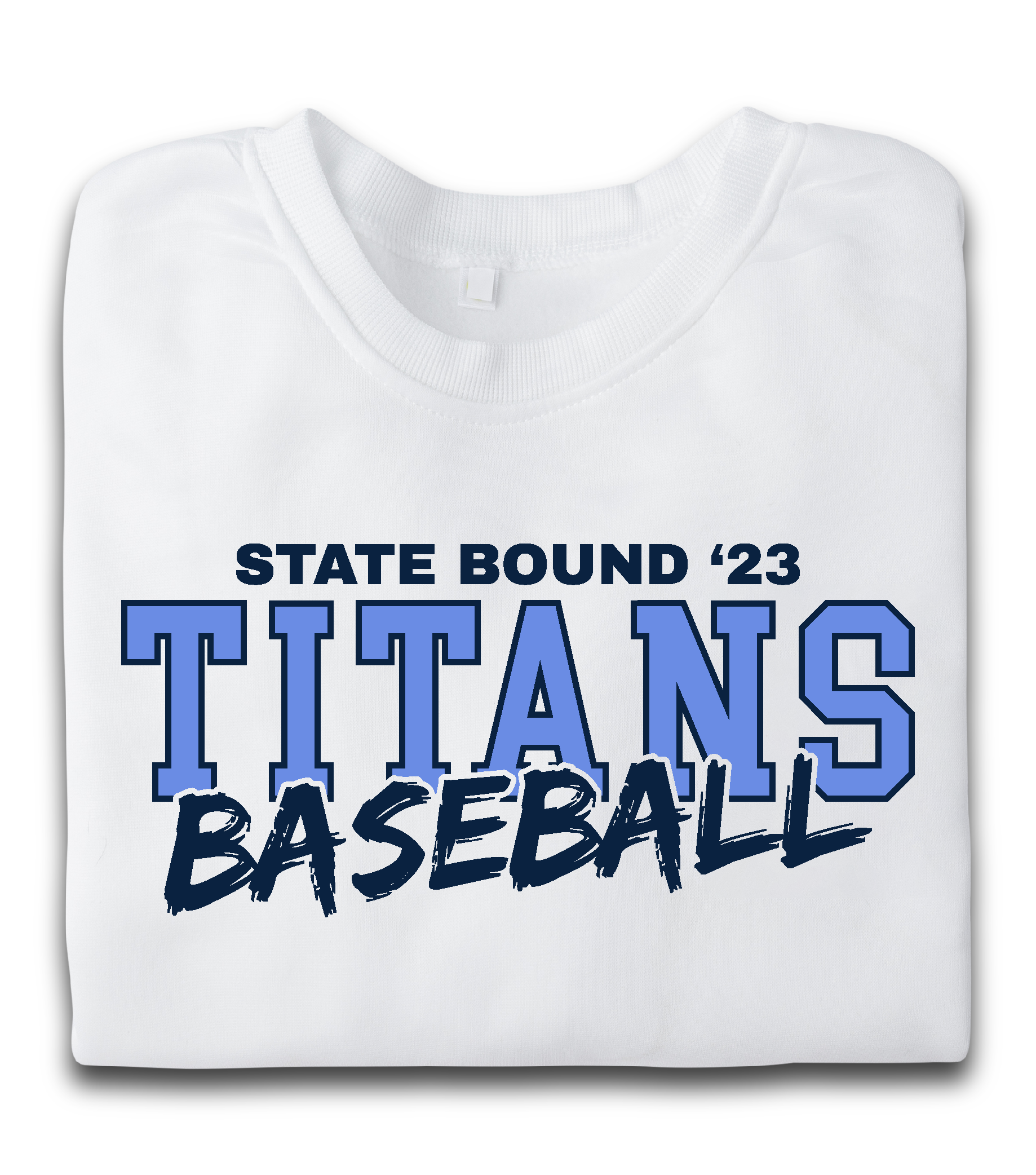

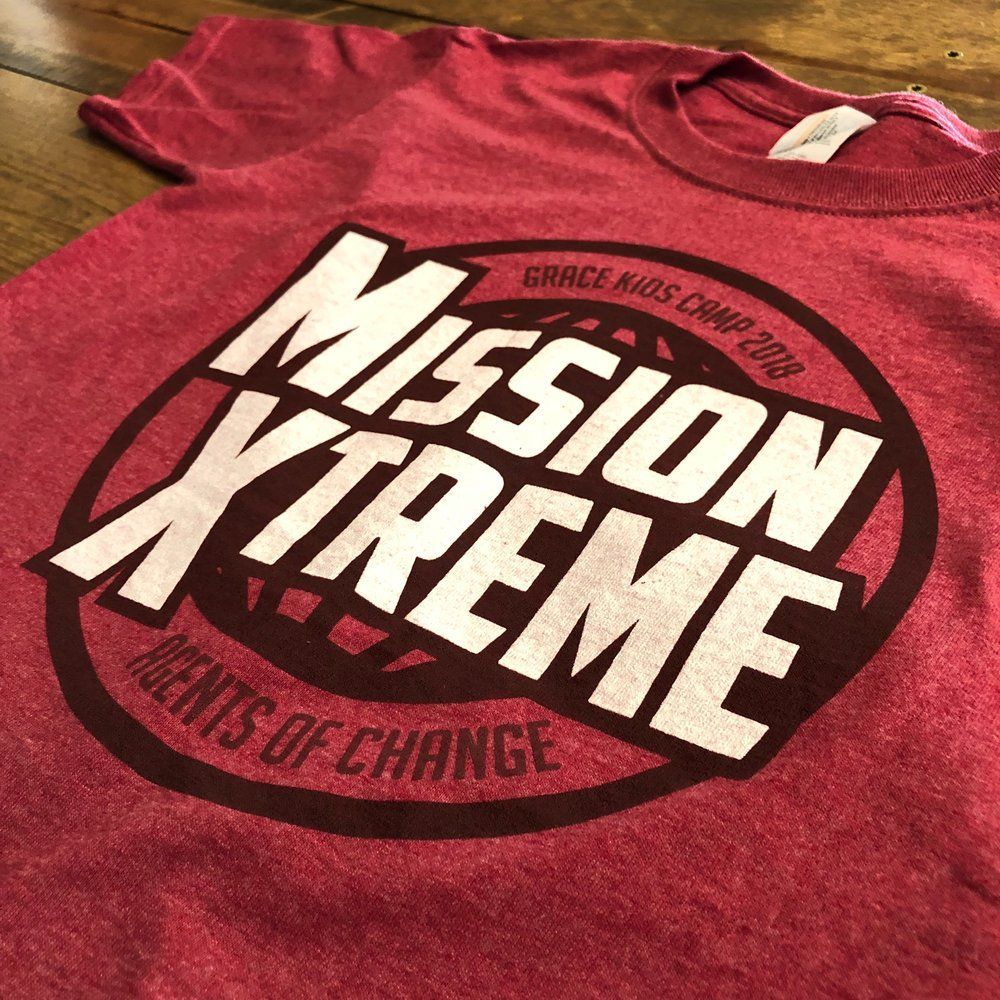

Plastisol is the traditional style of printing. Inks are thicker and rougher than our standard printing, and the ink sits on top of the shirt. These inks can be printed on any garment or fabric and work best in small print areas. Plastisol screen printing inks are typically used on all blended tees in place of our Standard inks.

Great people and great prices! My favorite printing company in town.

- Mike Nebraska

The Plastisol Screen Printing Process

Design Approval

The process begins with approving your design. Plastisol works best with bold designs, so we ensure your artwork is optimized for vivid and long-lasting prints.

Screen Preparation

Screens are created for each color in your design. Plastisol printing requires precise setup to ensure that each layer aligns perfectly for a clean, vibrant result.

Printing and Curing

Plastisol ink is applied to the garment, layer by layer. Each layer is then cured under high heat to ensure the ink adheres well to the fabric, providing a durable, bold finish.

Final Check

After curing, we inspect the garments for color vibrancy and print quality. Once approved, your products are ready for use or distribution.

Plastisol Screen Printing FAQs

What is plastisol screen printing?

Plastisol screen printing uses plastisol inks, which sit on top of the fabric for bright, durable prints.

Why choose plastisol screen printing?

Plastisol inks are highly versatile, providing vibrant colors and excellent durability.

Can plastisol inks be used on different fabrics?

Yes, plastisol inks work well on various fabrics, including cotton, polyester, and blends.

How do plastisol prints hold up over time?

Plastisol prints are known for their longevity and resistance to fading and cracking.

What is the typical turnaround time for plastisol screen printing orders?

Turnaround times vary based on the order but are generally prompt.